Mobile Theatre Rentals

With the difficulties of today’s changing market place, the versatility and cost savings of modular rental make it the solution that gives you maximum return from minimum outlay.

The underlying benefits are considerable :

- 30 square meter theatre

- Reduce your waiting list

- Single rental theatre from £14k per month

- Rental contracts from 6 months to 2 years

- Minimum deflection rigid floor construction

- Add on recovery area

- Up & running in 1 week

- Theatre manufactured with hot rolled steel frame

- Internal finishes all as permanent modular construction

- Permanent structure feel

Click here for our mobile operating theatre specification

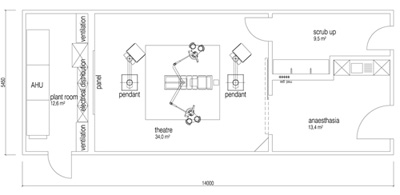

Description of Standard Mobile Rental Theatre Module 14055 BS

Theatre centre 14055 BS with associated rooms, consists of:

- Anaesthetic room

- Scrub up

- Theatre

- Plantroom

External finishes

- Mineral wool external insulation, covered with, rendered finish, colour white

- Eaves from Aluminium, approx. 200mm height

Carcass, structure

- Floor construction made from rust protected steel profiles, insulation with mineral wool, OSB - plate and vacuum concrete Fire resistance 60min, imposed floor load 350 kg/m2. External walls made from rust protected steel profiles, insulation with mineral wool and Fermacell boards Fire resistance 6Omin

- Roof construction made from rust protected steel profiles, insulation with mineral wool and Fermacell boards Fire resistance 6Omin, Roof load 125 kg/m2

- "0"-degree roof, sealed with a roof membrane, internal rain water drains

- Internal walls dry lining systems, boarding with Fermacell boards

Wall surfaces

- PVC-wall surface in the theatre, anaesthetic and scrub up room Eggshell white in the plantroom

- S/S edge protection, where necessary

Flooring

- PVC with welded joints, coved skirtings in the theatre, anaesthetic and scrub up room

- PVC with welded joints, standard skirting

Ceilings

- Suspended ceiling with metal tiles 62,5 x 62,5 in the theatre, anaesthetic and scrub up room

- SPlantroom solid ceiling painted white

Internal doorsets

Door between the scrub up and the theatre:

- Automatic doorset single swing with integrated window, electrical driven, controlled via switch, laminated surface, S/S frame

- Door between the anaesthetic room and the theatre:

- Manually operated sliding door with integrated window, laminated surface, S/S frame

- Door between the scrub up and the corridor:

- Manually operated swinging door, laminated surface, S/S frame

- Door between the anaesthetic room and the corridor:

- Manually operated swinging door, laminated surface, S/S frame

External door

Door to the plantroom:

- Insulated steel doorset, painted light grey

Electrical installation according to BS

- Distributions

- IPS and UPS

- Bender theatre control panel

- Wiring and cabling

- Clean room lighting, IP 65

- Switches, socket outlets for telephone and data only conduit system (installation by others)

- Emergency lighting

- Bonding

Ventilation and cooling according to BS

Hygienic ventilation and air conditioning system following the HTM 2025. We assumed the following technical basic data's:

- Fresh air summer: 28^; 50% rel. humidity

- Fresh air winter: -7 °C; 90 % rel. humidity

- Room temperature: 19 - 23 °C

- Rel. humidity: 40% - 60%

- Room class: I

- Supply air volume flow: approx. 4.500 m3/h

- Total air volume canopy: approx. 12.500 m3/h

Max. cooling load per theatre: 3,5 kW The system consists of the following components:

- 1 N° compact ventilation unit with integrated cooling and heating coils, filter class F7 and F9, heat recovery, humidifier, fans, condenser and control unit PC-3 Type: WEISS, Mediclean 75.3 DXL

- 1 N° clean air canopy for 12.500 m3/h, size 2,9m x 2,9m x 0,45m, Filter class H14 Type: WEISS, FFA.3 29/29

- 2 N° circulating air modules, pre filter F7, air volume 4.000 m3/h

- Duct work with insulation

- Other components like weather protection grids, silencer, fire damper, air flow controller, pressure stabilisizer, electric air heater

Sanitary installation

- The installation will be in the walls

- Supply and drain water system, where water is required

Heating

- Via ventilation system, static radiators where necessary

- Connection of the heating coils in the ventilation unit

Medical gases

- All installation with copper pipes according to British standard

- In the anaesthetic room wall outlets for O2, compressed air 5 bar, compressed air 10 bar (Air motor), Vacuum, N20 as well as the control panels for the medical gases

- In the theatre in the pendants

- Connecting point medical gases in the floor or the suspended ceiling of the anaesthetic room

The rooms are equipped with the following parts

Anaesthetic room:

- Cupboard with working plate and integrated wash basin integrated drugs cupboard and refrigerator

- 2 N° control panels for medical gases

- Anaesthetic working area equipped with: 2 N° rails for medical utilities

- 1 N° subconstuction for an anaesthetic machine Drager wall mounted gas outlets 2 N° O2

- 2 N° compressed air 5 bar 2 No Vacuum 2 N° N20

- 1 N° suction for anaesthetic gas

- Conduit system with 2 N° boxes for the telephone or data wiring (wiring and boxes are done by others)

Theatre:

- Canopy 2,9m x 2,9m

- Theatre light with satellite, DRAGER, Type SOLA 700/500

- Theatre control panel with X-Ray viewer, clock, alarms a.s.o.; type Bender

- 1 N° pendant Anaesthetic, DRAGER, Type Movita lift express max. loading: 80kg equipped with: 2 N° O2

- 2 N° compressed air 5 bar

- 2 N° N20

- 2 N° Vacuum

- 1 N° suction for anaesthetic gas

- 4 N° safety socket outlets

- 2 N° UPS socket outlets

- 6 N° earth connections

- 2 N° empty boxes (spare boxes for instance for IT connections)

- 1 N° pendant Chirurgie, DRAGER, Type Movita lift express max. loading: 80kg equipped with:

- 2 N° compressed air 5 bar 2 N° compressed air 10 bar (Air motor) 2 N° Vacuum 4 N° safety socket outlets 2 N° UPS socket outlets 6 N° earth connections 2 N° empty boxes (spare boxes for instance for IT connections)

- 4 N° socket outlets in the wall (safety circuit)

- 4 N° socket outlets in the wall (UPS)

- 8 N° earth connections in the wall

- 2 N° rails for medical utilities

- Bender theatre control panel

- Conduit system with 2 N° boxes for the telephone or data wiring (wiring and boxes are done by others)

Scrub up:

- Wash basin from S/S or Corian with 2 N° washing places

- 2 N° taps

- Thermostat for the adjustment of the water

Plant room:

- Electrical distributions connecting point of the external cables

- Electrical frost control unit

- Ventilation units

- Connecting point for heating energy

- Connecting point for water

Click here for our brief Specification for Modular Operating Theatre

Theatres include

Laminar Flow ultra clean canopy

Operating theatre light

Surgeons panel with x ray viewer

Anaesthetic room

Prep room

Automatic gas manifolds

Exclusions

Provision of med gas AP

28mm mains cold water supply

Main electrical supply 160 Kva per theatre, 90 Kva recovery, supply

requirements 400 amp TP & N

Supply of medical gas cylinders

Access ramps or reception link to Theatre / Recovery

Link corridors

Incoming comms connection